Advanced Electrochemical Testing

One of our core areas of expertise

Aqueous corrosion of metals is an electrochemical process, where an exchange of electrons occurs between an anode and a cathode. Therefore, electrochemical methods are being adapted not only to quantify metals corrosion rate but also to understand the mechanism of specific types of corrosion process (e.g., uniform and localised corrosion, crack formation, and tribocorrosion).

Researchers at the Curtin Corrosion Centre have a long-standing and internationally recognised experience in utilising conventional and advanced electrochemical methods in several industrial and fundamental research projects. Examples are electrochemical polarisation methods and more advanced techniques such as electrochemical impedance spectroscopy (EIS), zero resistance amperometry (ZRA), and electrochemical noise (EN). EIS, ZRA, and EN are powerful tools developed for continuous monitoring and assessment of corrosion rates and mechanisms, degradation of organic coatings, inhibitor research, etc.

The hardware

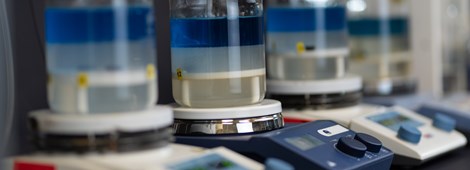

The Curtin Corrosion Centre has a vast array of potentiostats/galvanostats, high-impedance multimeters, oscilloscopes, rotating cylinders & disc electrode devices, and custom-made equipment. Examples include:

- Gamry Ref 600 and Ref 1200 potentiostats/galvanostats and multiplexers with EIS and ZRA capabilities.

- Bio-Logic VMP3 and SP-300 potentiostats/galvanostats with EIS and ZRA capabilities.

- PAR VersaSTAT 3F potentiostat/ galvanostat with EIS and ZRA capabilities.

- PARSTAT 3000A-DX Bipotentiostat for hydrogen permeation testing, EIS, and ZRA research.

- PINE rotating disk and cylinder electrode systems.

- Avesta cells (designed to avoid micro crevice corrosion formed between the working electrode and the gasket at the bottom aperture of the cell) as well as many standard and custom glass cells.

The methods

At the Curtin Corrosion Centre we use electrochemical tools to study, for example:

- localised corrosion of corrosion-resistant alloys.

- corrosion under insulation.

- inhibition efficacy and mechanisms.

- environmental cracking susceptibility of metals and alloys.

- tribo-electrochemical behaviour of passivating materials.

Additionally, to the advanced electrochemical techniques, the Curtin Corrosion Centre has expertise in designing complex fit for the particular conditions of the problem. Our researchers also work on sensor development for online monitoring of challenging phenomena such as top of the line corrosion and corrosion under insulation.

The list of test methods we conduct on a regular basis is too long!

Although we perform testing as per international standards, we excel at designing experiments to fit specific real-life challenges.

Contact us to learn more.