Stainless steel seal ring failure investigation

Background

Several leaks were detected at piping clamp connectors at a floating production storage and offloading (FPSO) vessel and rigid arm and riser turret moorings (RTM) during hydrostatic testing following wet lay-up in treated seawater. Further investigation revealed that crevice type corrosion had taken place on a martensitic precipitation hardening stainless steel UNS S17400 (SS17–4PH), nickel alloy UNS N07718 (NA718) and duplex stainless steel UNS S32205 (DSS) seal rings coupled to DSS hubs. Figure 1 illustrates the localised corrosion damage observed on a SS17–4PH part. Potential causes of failure included MIC, oxygen, galvanic corrosion and crevice corrosion, or a combination of these contributors.

Figure 1; Close up view of failed SS17–4PH Seal ring showing areas of crevice corrosion

The initial investigation

Samples from drained fluids (treated seawater) and corrosion products from failed seal rings were collected for microbiological analysis including microscopy, culture-dependent and culture-independent molecular analysis for identification of microorganisms present in samples. Failed seal rings and corrosion products were also analysed by scanning electron microscopy, and energy dispersive X-ray spectroscopy (SEM-EDS) elemental X-ray mapping, X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and Raman spectroscopy.

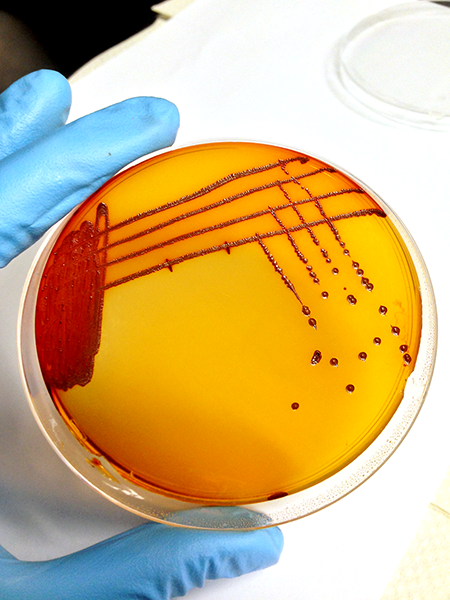

Corrosion products exhibited high numbers of sessile bacteria (105–108 cell/mL) although no active microbes were detected in drained fluids. Dominant microbes identified corresponded to species of Pseudomonas, Marinomonas and Hyphomicrobium. These microorganisms were isolated, and all displayed effective Iron-oxidizing capabilities. Figure 2 shows Pseudomonas species grown on agar plates with iron precipitation evident in the medium.

Figure 2; Pseudomonas species grown on agar plates with iron precipitation evident in the medium.

A laboratory investigation was then undertaken to shed more light on the causes and contributions to the seal rings corroding. The effect of oxygen, crevices, galvanic and microbes was assessed individually and in combination at conditions simulating wet lay-up in seawater. Corrosion was studied using electrochemical measurements, including open circuit potential (OCP) and galvanic current density, and 3D surface profilometry.

The findings

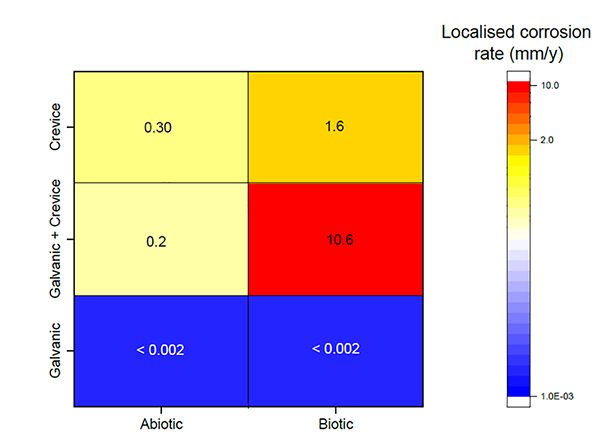

The investigation concluded that the corrosion attack was triggered by the introduction of oxygen, which was further accelerated by the combined action of microbes, galvanic, and crevice effects. The results confirmed iron-oxidising bacteria played a critical role in the accelerated corrosion observed on the seal rings, as illustrated in Figure 3. Figure 3 shows the relative and mutual influence of bacteria and galvanic coupling on crevice corrosion during simulated wet lay-up (aerated conditions). In the laboratory experiments, a maximum localised penetration rate of 10.6 mm/y was recorded for creviced SS17–4PH only when coupled with DSS and in the presence of bacteria (biotic condition).

Figure 3; Relative and mutual influence of bacteria and galvanic coupling on crevice corrosion during simulated wet lay-up (aerated conditions)

Lessons learned

The work demonstrated to the client the conditions that caused the failure of the seal rings. It also highlighted the importance of maintaining the integrity of chemical treatment (particularly oxygen scavenger and biocide) during wet lay-up and the importance of material selection for piping clamp connectors.

The client was able to share the learnings across the company and emphasised the importance of implementing the correct flushing and preservation procedures applicable to pressure equipment and piping systems.

Would you like to learn more? Contact us today!